Jan. 20, 2022

Gate valve globe valve Both globe and gate valves can be used in pipelines to cut off the flow of media, as gate and globe valves also have a similar structure. Therefore, for some newcomers to the industrial valve market, the difference between globe and gate valves can be really confusing. Compare the difference between globe valve and gate valve from four aspects.

1. Difference in structure

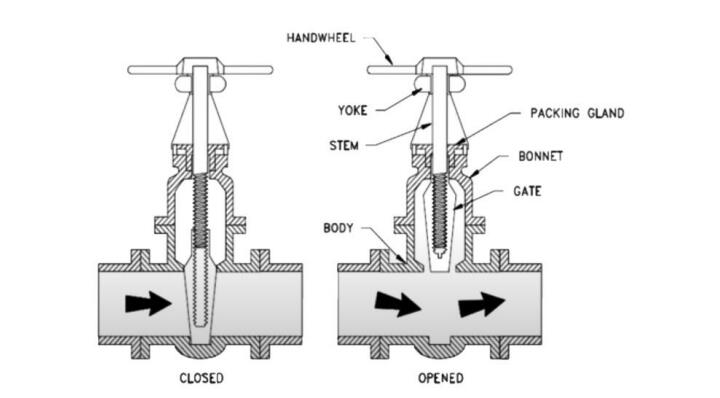

The structure of gate valves is more complicated than that of globe valves.

First, there are two types of gate valves according to their structure: rising stem gate valves and non-rising stem gate valves, but globe valves do not have this different design.

Second, in appearance and construction, the gate valve has a shorter end face (length) than the globe valve, but a higher height than the globe valve.

As a result, gate valves require more space for installation, especially rising stem gate valves.

The rising stem gate valve is also known as the OS&Y design, which means outer stem and yoke.

2. Difference in Principle

Gate valves and globe valves operate in the same way, both can use pneumatic actuators, electric actuators or handwheels to drive the stem to open and close the valve.

The difference between them is that gate valves can only be fully open and fully closed. Its stroke/stroke is greater than that of a globe valve. It means that the gate valve has a longer opening and closing time than the globe valve.

Since the distance from the valve plug to the valve seat is shorter than in a globe valve, the globe valve can globe at any stroke during its movement to throttle the flow. This is not available in gate valves.

In addition, when the gate valve is installed in the pipeline, there is no requirement for the inlet and outlet direction, and the medium can circulate in both directions. But globe valves definitely have an inlet and outlet direction. The flow direction of a globe valve can be from bottom to top or from top to bottom. Most flow types of globe valves are from bottom to top.

3.Difference in flow resistance

Because the gate valve can only be fully open and fully closed, when it is in the fully open state, the flow path in the entire pipeline is straight. When the medium flows through the valve body, there is almost no obstruction, and the flow resistance is almost zero. In the globe valve, the medium flows through the valve body, the flow direction is from top to bottom, and the resistance of the spool is relatively large.

4. Difference in maintenance costs

Gate valve in maintenance and repair, the gate valve needs to be completely disassembled from the pipeline, the labor cost is relatively high. However, for globe valves, in most cases, the seat and spool can be replaced directly on site without disassembling the entire valve. Therefore, globe valves are suitable for welded connection applications.

Both ball valves and globe valves shut off fluid from the pipeline.

The ball valve is an evolution of the plug valve. Its opening and closing part is a ball, which is rotated 90° around the stem axis to open and close the valve.

Advantages of ball valves.

1. The ball valve has the lowest flow resistance.

2. Can be opened and closed quickly.

3, the ball valve is compact and light weight, and can be considered the most reasonable valve structure in the low-temperature media system.

4, the ball valve body adopts asymmetric design, especially the welded body structure, which can well withstand the stress from the pipeline.

Disadvantages of ball valves.

Throttling performance is worse than the globe valve, especially the pneumatic globe type control valve (or electric globe type control valve).

Globe valve is used to cut off the flow of the medium, suitable for occasions that require very frequent opening. Most commonly used in chemical plants.

Advantages of globe valves.

1, simple structure, easy to manufacture and maintain.

2, small working stroke, short opening and closing time.

3, good sealing performance, sealing surface and plug friction is small, long service life.

Disadvantages of globe valve.

1.High fluid resistance, the force required to open and close is large.

2. not applicable to the media with particles, high viscosity, coking media.

3.High fluid resistance, the reliability of the seal is not suitable for long-term operation.

Both globe valves and butterfly valves are common valves in industrial processes. What is the difference between globe valve and butterfly valve? Both globe valves and butterfly valves are similar in function, and both globe valves and butterfly valves can be used for flow regulation or shutoff. The difference is that globe valves have better flow regulation when used to control flow. The advantages of butterfly valve are wider application, larger flow capacity, shorter structure length and simpler structure.

The globe valve allows only one-way flow of the medium when installed. The opening and closing stroke of the globe valve stem is relatively short and has a reliable shut-off function. Since the response of the valve seat is proportional to the stroke of the spool, it is very suitable for flow regulation. Therefore, this type of globe valve is very suitable for cut-off or regulation throttling. The construction length of globe valves is greater than that of butterfly valves.

The butterfly valve is a rotary motion valve, which consists of four main parts: the valve body, stem, plate and seat. The butterfly valve has a disc mounted on a rotating shaft. When the butterfly valve is completely closed, the valve plate returns and completely blocks the pipeline. When the butterfly valve is fully open, the plate is at a right angle to control the flow of gas or liquid.

Butterfly valve is a simple regulating valve, also can be used for low-pressure pipeline media on and off control. There are many types of butterfly valves for a wide range of applications. Butterfly valves are used in pipelines carrying various corrosive and non-corrosive fluid media in engineering systems such as generators, natural gas, petroleum, air, chemical, power plants, etc., for controlling and passing through the media. Butterfly valve has two-way seal and single-way seal.

Plug valve is suitable for the nominal pressure CLASS150-1500LBS, working temperature -29 ~ 550 ℃, petroleum, chemical, pharmaceutical, fertilizer, electric power and other working conditions of various pipeline media cut off or connection.

The total plug valve has compact structure, small volume, and compared with the gate valve, the valve height is greatly reduced, and the fluid resistance is also greatly reduced.

Plug valve is a rotary valve, the plug is shaped like a cone or cylinder. It can be rotated in the valve body to control the flow of fluid.

The opening process of the plug valve: To open the valve, you need to turn the handwheel to make the plug rise up and off the sealing surface. The handle is rotated 90° so that the passage of the plug is connected to the passage of the valve body to open. The process of closing the valve is to turn the handle 90° so that the passage of the plug is perpendicular to the passage of the valve body, and then turn the handwheel so that the plug descends to achieve sealing.