May. 10, 2024

Soft-sealed elastic seated gate valves are mainly used in water supply and drainage systems. Temperature ≤80℃,

nominal pressure ≤PN25, diameter ≤800mm. The valve body material is cast iron or ductile iron, cast steel or stainless steel.

Adopted standards: CJ/T216-2013 soft-sealing gate valve for water supply and drainage, GB/T 24924-2010 elastic-sealing gate

valve for water supply system. AWWA C509:2001.

Main features: The outer surface of the metal gate adopts molding vulcanization or injection vulcanization molding process,

and is entirely covered with rubber EPDM

or NBR. When closing, the sealing is completed by elastic deformation of the rubber on the gate sealing surface. Corrosion-resistant,

good sealing, zero leakage can

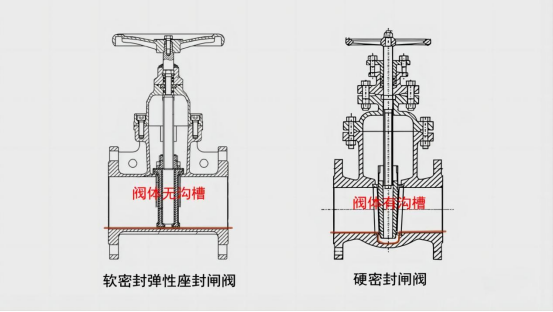

be achieved. The gate plate is wedge-shaped, which reduces the wear of the valve plate sealing surface. There are no grooves

at the bottom of the valve body. Fine

particles in the medium will pass through the valve body along with the medium without accumulating impurities. The inner diameter

of the flow channel at the valve

seat is equal to that of the pipe and is consistent with the nominal size. Almost no flow resistance.

The gate valve stem position is sealed with three O-rings. Effectively prevent leakage at the valve stem position. At the same time, a

dust ring is set on the top to prevent impurities and dust from entering. Can be replaced online under pressure.

The main replacement of elastic soft seal gate valve is: GB/T12232-2005 general valve flange connection iron gate valve. Including

nominal pressure PN1 ~ 25,nominal diameter DN50 ~ 2000 flange connection gray cast iron and ductile iron gate valves.

The main differences between the two are:

The gate plate of the soft-sealed elastic seated gate valve is entirely wrapped with rubber, forming a soft seal with the sealing surface

of the valve body, and has good sealing performance. During maintenance, it is generally only necessary to replace the gate with a new

one, which is easy to maintain. The hard seal gate

valve body and gate plate sealing surface are made of body material, copper alloy and stainless steel. After wear and tear, the valve

body and gate need to be repaired at the same time, which is relatively complicated.

The body of the soft-sealed elastic seated gate valve adopts a groove-free design. Will not cause impurities to accumulate. Due to the

sealing surfaces on both sides of the valve body, the hard-sealed gate valve has grooves at the bottom of the valve body. Over

time, some impurities will be deposited in the grooves. Block the gate from falling, causing sealing failure.

The body of the soft-sealed elastic seated gate valve is sprayed with epoxy resin paint. Epoxy resin coating is corrosion-resistant,

pollution-free, and can be used in tap water pipes. Hard-sealed gate valves are mostly spray-painted, which pollutes water quality

to a certain extent, but now hard-sealed gate valves in tap water pipelines are also sprayed with epoxy resin.

The standard for soft-sealing elastically seated gate valves stipulates that the valve stem shaft seal must have at least three O-ring

seals, which can be replaced when the gate valve is fully open under working pressure. The hard seal gate valve standard

GB/T12232-2005 stipulates no less than two sealing rings. Also provide a dust seal.

The upper valve cover of the soft-sealed elastic seated gate valve adopts hexagon socket screws. After tightening, wax is poured

on top to seal. This prevents rust between the screws and the valve body threads. Convenient for later screw removal and repair.

The original hard seal gate valve usually uses hexagonal bolts.However, there are also some hard-sealed gate valves with similar

structures.

The applicable medium temperatures are different. On water pipelines, soft seal gate valves are increasingly used. Hard-sealed

gate valves for some high-temperature media pipelines are also the main products.