Resilient Seated Gate Valve Introduction

Resilient seated gate valves made of speclal rubber elastlcly full wrap-plece valve structure, and the general absence of gate leakage or rust compared to other phenomena. Overcome their common seal bad, elastic fatigue, wear rubber aging and Sealing ruts and other defects. Produced by ths elastic saeling full compensation of small quantities of deformation to achieve a good sealing effect. It can be widely used in water supply, petrochemical, metallurgy, shipbuilding, food, pharmaceuticals and energy systems and other fluid line is used as a regulator and shut-off devices.

Resilient Seated Gate Valve Features

1. The overall package of plastic: the spool and the latest high-performance rubber vulcanization technology overall coating. laminating are tight. accurate geometry, rellable sealing and long service life.

2. Light weight: body ductile iron material, gate valve to reducs weight than tha average 25%, easy installation and maintenance; gate valve maximum opening helght is generally low 60mm ~ 280mm, can be installed where space is limited.

3. Flat style seat: The bottom of the pipe the same flat style seat design, does not produce debris accumulation, flow channel unimpeded and reliable sealing.

4. Corrosion resistance: the valve cavity using non-toxic epoxy powder coating, inner parts mining copper alloy and stainless steel to prevent corrosion and rust.

5. The three 'O' seal: the use of the stem seal O-ring seals, friction is small, lightweight and watertight gwitch.

Resilient Seated Gate Valve Performance specification

| Nominal pressure | Test pressure | Nominal diameter | Temperature | Medium |

| PN(Mpa) | Shell | Seal | DN(mm) |

| 1.0 | 1.5 | 1.1 | 20-2000 | ≤80℃ | Sundry Water and

Sewage |

| 1.6 | 2.4 | 1.76 |

| 2.5 | 4 | 4.75 |

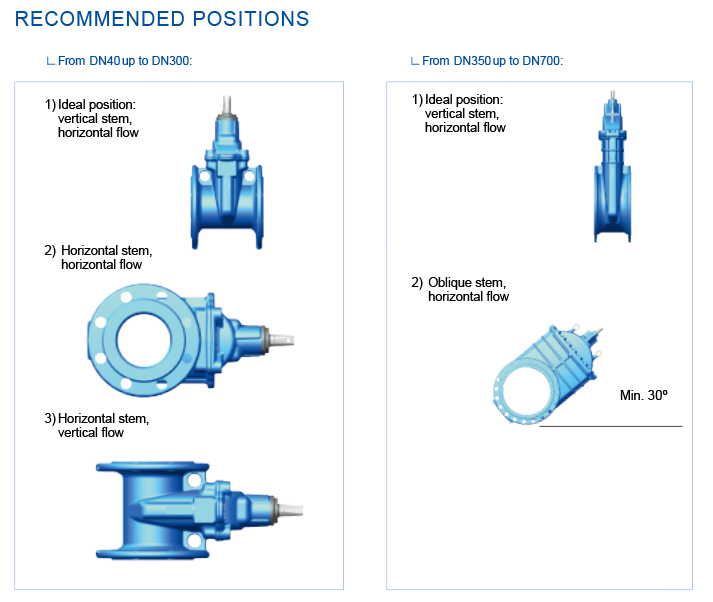

Resilient Seated Gate Valve RECOMMENDED POSITIONS

FAQ of Resilient Seated Gate Valve

The following checks should be carried out during installation:

Whether the connecting bolts are evenly tightened.

Check whether the packing is tight.

After compaction, the sealing of the packing should be ensured and the rotation of the valve stem should not be blocked.

Check regularly after installation:

Wear of sealing surface

The wear of the trapezoidal thread of the valve stem and the valve stem nut.

Wear of trapezoidal threads of valve body and bonnet nuts.

Wear of trapezoidal threads of valve body and bonnet nut.

Whether the packing fails due to long use.

After the valve is overhauled and assembled, a sealing performance test must be carried out. After each overhaul, the overhaul will be recorded in detail for future reference.

Related News of Resilient Seated Gate Valve

The Main Difference Between Gate Valve Metal Seat and Resilient Seat